Coldrunner

The history of M. Huber I.T.Σ. GmbH started in 1994 with the development of a cold runner system which had to be easy to handle at a reasonable price. The result of this development is known as the hybrid cold runner system ( HKS ). Today M.Huber I.T.S. GmbH offers 3 basic types of cold runner systems.

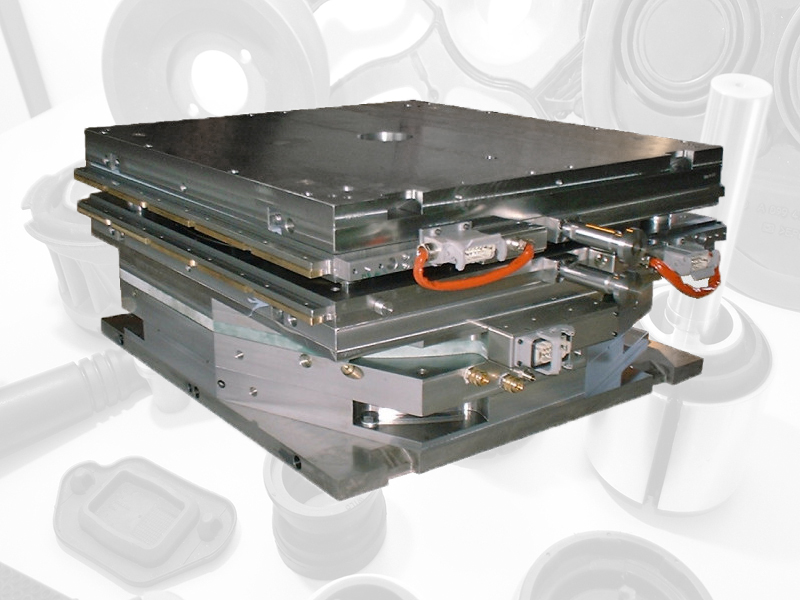

HKS (Hybrid Coldrunner System)

Reliable and due to the design it has proofed to be easy to clean, it also allows to facilitate nozzle lay outs which have been not possible with existing deep hole drilled systems. Using this design, completely vulcanized cold runner blocks are now not cleaned with mine workers technology, using extended drills and chisels. The HKS enables you to dismantle the complete runner system and clean it with a certainty of 100% not damaging the walls of the runners.

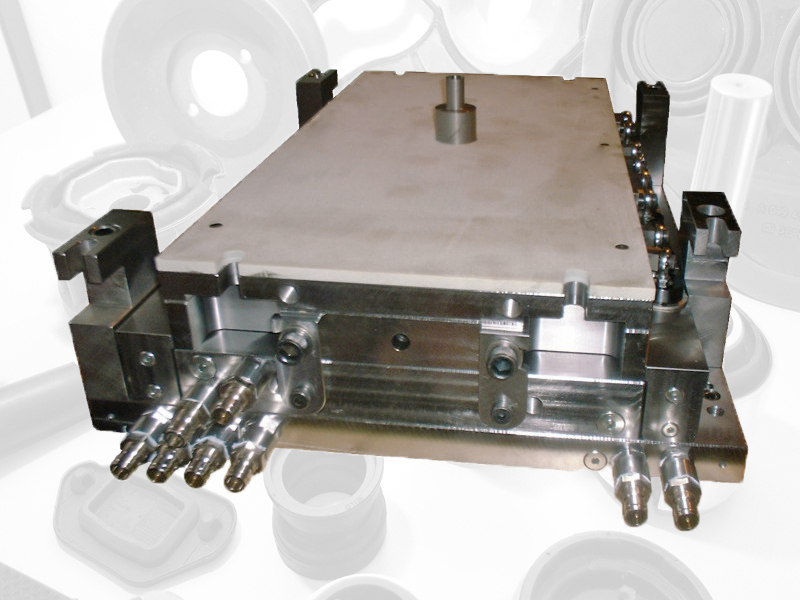

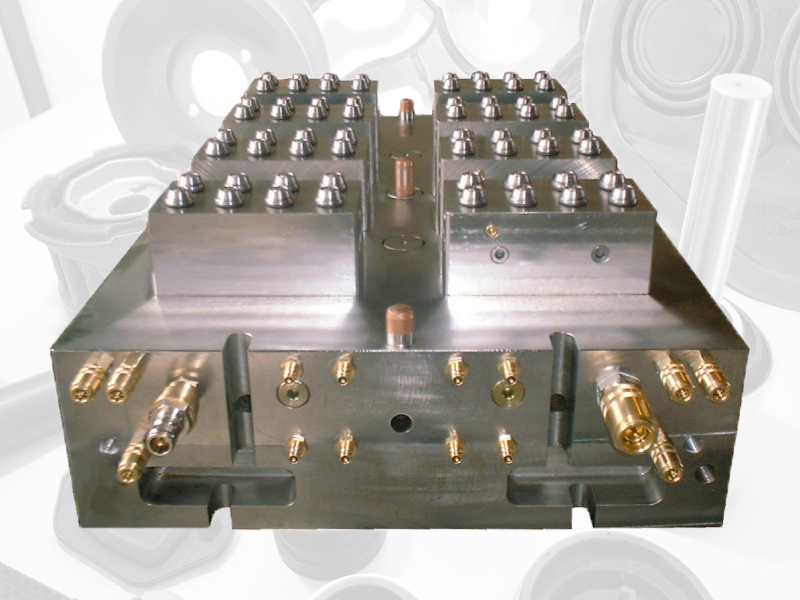

NVD (Valve Gate Nozzle)

Versions

Modifying the basic systems at numerous amount of variations customized to your needs are possible.